Winston-Salem’s Novex Innovations Helps Clients Move Products to Market

When URO-1 Medical of Winston-Salem needed help commercializing its new medical device, the startup company didn’t have to look far for it.

Across the street and around the corner, in the city’s Wake Forest Innovation Quarter, was Novex Innovations, a contract development and manufacturing organization that helps life science companies like URO-1 get their products to market quickly and inexpensively.

URO-1 engaged Novex to advance its Repris Bladder Injection System, an instrument that works with endoscopes to allow precise injections of Botox into the bladder wall to treat overactive bladder.

“From our perspective it’s a great partnership,” says Ted Belleza, president and chief executive officer of URO-1. “It’s a great marriage.”

After a recent move by URO-1, the two companies now work from the same building, Albert Hall, a revitalized factory once used by R.J. Reynolds Tobacco Co. for making tin cans for its Prince Albert pipe tobacco. URO-1 works on the ground floor while Novex occupies about 4,000 square feet on the third floor.

Belleza says URO-1 will rely on Novex for market testing, manufacturing and shipping of Repris when the product is fully commercialized in 2019. The device was approved for sale this spring by the U.S. Food and Drug Administration with the help of Novex’s regulatory expertise.

“Having resources like Novex Innovations within close proximity to our nearly 80 diverse biotechnology companies in the region provides greater potential for product ideas to be accelerated,” says Nancy Johnston, executive director of the North Carolina Biotechnology Center’s Piedmont Triad Region Office. “The URO-1 collaboration is a good example of a positive outcome.”

A growing client list

URO-1, which received a $250,000 Small Business Research Loan this year from the Biotech Center, is one of more than 50 clients that Novex has attracted during its first four years.

“With the amount of customers we have, the number of projects we have and the number of people we have, it’s extremely busy here,” says Doug Drabble, Novex’s director of manufacturing, who also oversees daily operations.

On any given day, Novex’s 11-member staff works on projects for seven or eight customers, handling procurement, development, manufacturing, storage and distribution for them.

“We can accommodate whatever people are needing,” Drabble says. “We do almost everything in-house.”

The work includes processing about two to three dozen product shipments daily and managing inventory for 78 different products, most of which are manufactured and packaged on site.

“The UPS and FedEx guys are here every day,” along with other couriers, Drabble says.

Devices and diagnostics account for about 40 percent of Novex’s work, followed by aseptic formulations, tissue and bioengineered products, active pharmaceutical ingredients, and dietary supplements and natural products.

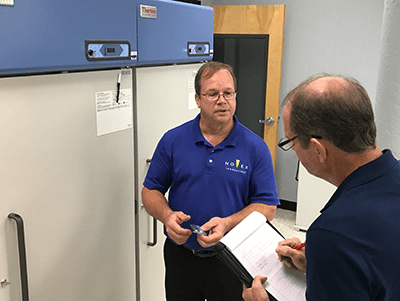

in a Novex lab.

Current or upcoming projects include diagnostics for measuring carbon dioxide levels in breath and glucose levels in blood; a device for keeping organs cool and fresh for transplant; a medium for supporting cells and tissues; active pharmaceutical ingredients for cancer drugs; preserved nerve tissue for repairing severed nerves; sheets of cultured skin for treating burns; and medical devices such as URO-1’s Repris system.

The company initially targeted its services to doctors, inventors and university spinout companies – a niche market it believed was under-served. Since then it has attracted small, medium and large companies including three multi-billion-dollar companies.

Drabble recalls one recent site visit by a large company that brought 14 employees – more than Novex’s entire staff – to assess Novex’s capabilities.

“We blew them away with how we did things,” he recalls. “They said, ‘if only we could do what you do at this place.’ We got that work, and it’s coming to fruition now. According to them, we’ve been one of the most responsible vendors they’ve had.”

“It’s not how much you spend,” he adds. “It’s what you do for your customers.”

Novex doesn’t turn away small clients with less profitable projects because even they can make innovations that can improve lives, Drabble says.

“I think there’s a lot of value in supporting the health of the general population,” he says.

The eyes have it

The company originated in 2010 as a small business unit of Ocular Systems, a Winston-Salem company that processed corneal tissue for transplants. When Ocular Systems was sold in 2014, the business unit was spun out as a separate company and named Novex.

Both companies were founded by Jerry Barker, an entrepreneur with experience in eye banking, medical device development and regulatory submissions.

GMP-compliant facility can handle projects in all stages of development

ranging from process and product development to Phase 3 clinical trials,

including fill and finish operations and commercial cell therapy manufacturing.

One of Novex’s initial clients was a North Carolina eye surgeon who had invented a medical device but was having problems finding vendors capable of commercializing it. Novex stepped in with regulatory and manufacturing help in 2014, and within three months the product was approved by the FDA, Drabble says.

Since then, other diverse clients – a third of them from North Carolina – have come on board.

“Most of it is by word of mouth and reputation,” he says.

Novex’s staff has grown from two half-time employees to eight full-time employees, three part-time employees and an intern. The company plans to hire two more full-time employees as business grows, Drabble says.

To broaden its capacities for new projects, Novex is seeking various registrations from the FDA and other regulatory agencies around the world. It’s also mulling an expansion of up to 11,000 square feet on the third and second floors of Albert Hall to accommodate more work.

Meantime, the company is in an enviable position for a young life science company: self-financed and debt free.