North Carolina Clinical Team Plays Texas-sized Role with TFF Pharmaceuticals

A Texas pharmaceutical company is leaning on its North Carolina-based preclinical and clinical development teams to advance a novel drug-delivery technology that could make medicines safer and more effective.

TFF Pharmaceuticals, a clinical-stage company founded in 2018 and headquartered in Fort Worth, has about 10 employees and contractors working in North Carolina, mostly in the Raleigh area, accounting for almost one-third of the company’s 35 employees.

The North Carolina team is responsible for the company’s preclinical, clinical and regulatory operations, as well as chemistry, manufacturing and controls. It is focused on developing applications of TFF’s thin film freezing technology, a platform that transforms new or existing medicines into dry powder formulations for more-effective delivery to targeted organs and tissues.

“TFF’s technology has the potential to do a great deal of good for patients in need,” said Tony Hickey, Ph.D., the company’s chief scientific officer. “Our primary objective is keeping the patients at the forefront of our work.”

TFF’s top Tar Heels

Hickey, who joined TFF in 2022, is based in the Research Triangle region, where he has held several academic and entrepreneurial roles.

He is an emeritus professor of molecular pharmaceutics at the University of North Carolina at Chapel Hill’s Eshelman School of Pharmacy and an adjunct professor of biomedical engineering at the UNC School of Medicine. He is also a distinguished fellow and program director in inhaled therapeutics in the Center for Engineered Systems at RTI International.

He has scientific expertise in pulmonary biology, aerosol physics, powder dynamics, pharmacokinetics and drug disposition, formulation design and device development.

Hickey is also a serial entrepreneur who founded three North Carolina bioscience companies: Cirrus Pharmaceuticals, later acquired by Kemwell; Oriel Therapeutics, later acquired by Sandoz; and Astartein.

Another North Carolina scientist with entrepreneurial company experience in the state, Dale J. Christensen, Ph.D., serves with Hickey on TFF’s management team and is head of preclinical development.

Christensen previously held senior positions at six North Carolina bioscience start-up companies: Affinergy, Aryzun Pharmaceuticals, Cognosci, KaroBio USA, Oncotide and Spyryx Biosciences. He is also an adjunct associate professor of medicine at Duke University Medical Center.

Aiming for better drug delivery

TFF’s dry powders are intended to overcome the limitations of other drug formulations.

Many drugs don’t reach their target effectively due to inferior physical properties, leading to compromised bioavailability, slow onset of action and suboptimal efficacy, according to the company.

Nearly 40% of marketed drugs and 90% of drugs in the discovery pipeline are poorly water-soluble. Consequently, they are often given in high doses, increasing the risk of toxicities and adverse side effects.

Many biologic-based therapies, including proteins, RNA, vaccines, viruses, and others, also face stability, structure and activity problems when delivered in liquid form. TFF’s technology can transform small molecules, biologics and combination therapies alike.

The company’s thin film freezing process yields engineered drug particles that can be delivered in dry powder form directly to the target organ, potentially providing better solubility, absorption, stability and safety.

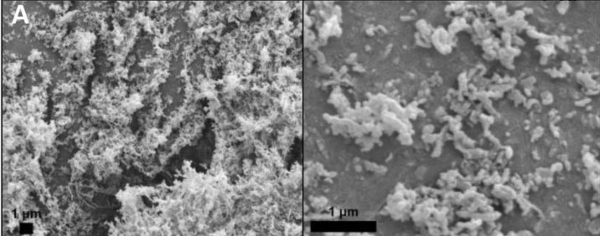

The process involves first combining a drug or drugs in a liquid carrier system, which can include agents designed to promote dispersion and avoid aggregation, as well as excipients to promote delivery to the target site. Controlled freezing of the liquid on the surface of a cryogenic drum produces what the company calls brittle matrix particles: highly porous, low-density particles with a large surface area.

The frozen solvent is then removed by sublimation to yield a dry powder that can be aerosolized for delivery to the lungs, nose and eyes, and topically through the skin. The brittle matrix particles are further processed into a final dosage form for the targeted route of administration.

According to TFF, its products offer advantages over other dry powder treatments made through traditional methods such as spray drying, spray freeze drying and nano-milling. They have a uniform particle size with higher yield and better absorption, and they allow gentler processing for labile, or easily broken down, molecules.

The proprietary technology was licensed from the University of Texas at Austin, where it was invented in the lab of Robert “Bill” Williams, Ph.D., a professor of pharmaceutics and the division head of molecular pharmaceutics and drug delivery in the College of Pharmacy. It is protected by more than 120 patents issued or pending in the United States and internationally.

“Thanks in no small part to Bill's team’s prolific research activities and extensive publications, thin film freezing is now widely recognized as one of the most important advances in pharmaceutical formulation technology over the last several decades,” TFF’s chief executive officer and board chair, Harlan Weisman, M.D., said in a February conference call with analysts.

Two drug candidates in development

Hickey, Christensen and their fellow North Carolinians on TFF’s preclinical and clinical development teams are focused on advancing two internal drug candidates, both in Phase 2 clinical studies.

TFF VORI is a dry powder formulation of voriconazole to treatment and prevent invasive pulmonary aspergillosis, a severe fungal pulmonary disease. Compared to oral forms of voriconazole, TFF’s inhalable formulation reduces the risk of systemic exposure and drug-drug interactions and yields better efficacy with a lower dose, Hickey said.

The second drug candidate, TFF TAC, is an inhaled dry powder version of tacrolimus, an immunosuppressive drug used in transplant medicine. TFF TAC specifically targets lung tissue, yielding improved immunosuppression with less systemic exposure and risk of side effects, Hickey said.

The company expects to announce Phase 2 proof-of-concept data for both drug candidates later this year. Read-outs should provide safety, tolerability and efficacy results.

“I am excited to see the ongoing progression of our TFF VORI and TFF TAC programs and to generally help our team advance the full potential of our thin film freezing technology, which represents a truly standout opportunity in dry powder aerosol delivery,” Hickey said.