RTP Startup restor3d is Personalizing the Surgical Process

Medical device startup restor3d wants to make the surgical process more personal – and more effective.

The Research Triangle Park-headquartered company is using 3D printing, artificial intelligence (AI), and machine learning (ML) to design patient-specific surgical implants and related instruments across multiple fields of medicine.

Restor3d co-founder and Chief Technology Officer Ken Gall, Ph.D., believes this more individualized approach to surgery will soon replace the current one-size-fits-all way of repairing the human body. “It’s a very customer-centric model,” he said.

Gall, who has founded several other medical device startups in his career, also is professor of mechanical engineering at Duke University. Restor3d co-founder Andrew Miller, Ph.D., is the company’s chief operating officer. Entrepreneur and investor J. Kurt Jacobus, Ph.D., is CEO.

Since its creation in 2017, the company – originally known as Additive Device – has concentrated on developing 3D printed medical devices, created with advanced biomaterials, and designed specifically for the patients who receive them.

The current emphasis is on orthopedics. But restor3d’s TIDAL Technology, coupled with its AI and ML software, can be used to repair almost any part of the musculoskeletal system, according to Senior Vice President of Product Development Brian Garvey.

In 2021, the company merged with the total ankle replacement company Garvey founded, Kinos Medical, which was based in Pennsylvania. The combination increased restor3d’s footprint in the high-growth U.S. foot and ankle market.

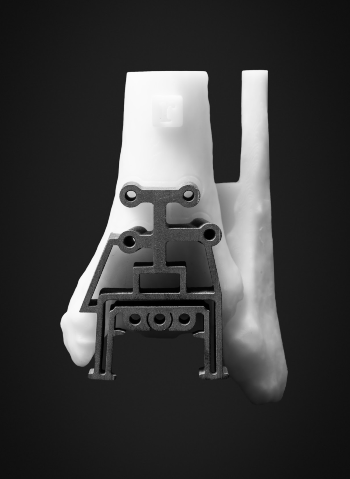

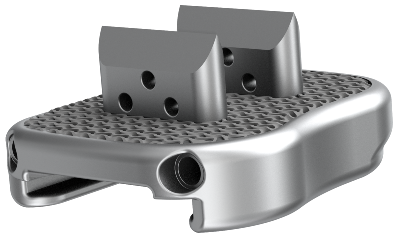

It recently received 510 (k) clearance from the U.S. Food and Drug Administration, which confirmed the safety and effectiveness of its Axiom PSR (patient-specific resection) System. These titanium alloy instruments are designed, in direct collaboration with surgeons, to ensure the ideal anatomic fit and positioning of implants in their patients who undergo total ankle replacements using the Kinos Axiom Total Ankle System.

Restor3d says the individualized instrumentation also helps reduce the time required for total ankle surgeries and improves results.

“The convergence of our inhouse 3d printing capabilities, advanced engineering and clinically focused research teams allows us to provide these next-generation patient-specific devices,” Garvey pointed out.

The Axiom PSR System and the company’s other products are 3D printed and manufactured primarily by restor3d, which it is in the process of relocating from its current downtown Durham headquarters to a larger complex in Research Triangle Park. Garvey said the move should be completed this summer.

The new 50,225-square-foot facility will be used for patient-specific digital design, product development, implants and instruments manufacturing, and surgeon training and education. The fast-growing company currently employs close to 150 people in the Research Triangle area.