Inside a $3.2M Raise: Lindy Biosciences’ CEO Tells What’s Next for the Duke Spinout Developing Microglassification Tech

Flush with cash, Duke spinout Lindy Biosciences is getting ready to scale.

This week, the Research Triangle Park-based biotechnology company, launched in 2017, confirmed it closed on $3.2 million to continue developing and scaling its microglassification dehydration process. The aim: to produce high-dosage, lower-volume medicines.

The raise comes on the heels of raising a $1.6 million Series A round in 2020 and receiving a $200,000 loan from the North Carolina Biotechnology Center to get it off the ground.

Lindy said its technology would enable a number of antibody therapies to be delivered at home via a self-applied injection rather than in an acute-care setting using slow intravenous (IV) infusions. Doing so, it said, will decrease administration costs, increase patient comfort and compliance, and enable new high-dose molecules to reach the market.

Its founder Deborah Bitterfield, Ph.D., spoke to NCBiotech this week about the startup’s latest developments. Here’s what she had to say:

Take us back to the beginning. How did you end up starting Lindy Biosciences?

Bitterfield: I did my Ph.D. research at Duke in Dr. David Needham’s lab—he’s the inventor of the dehydration technology we are commercializing. At that time, Southeast TechInventures (STI) had a [$800,000] SBIR grant in collaboration with the Duke lab to look at the technology as a preservation method for biologics, so they hired me as the principal investigator after I graduated. After a few industry collaborations, we realized there was far more potential for the technology in drug delivery. Specifically, there was a tremendous need for high-concentration delivery of biotherapeutics. Neil Jones (our VP of Corporate Strategic Partnerships) was consulting with STI at that time. With promising early data, we decided to spin off Lindy and build a company around innovative science, with a viable path toward impacting patients.

In Lindy's early days, the North Carolina Biotechnology Center awarded the company $200,000 through a business research loan. How critical was this cash infusion to getting the startup off the ground?

Bitterfield: The NCBiotech loan was tremendously helpful in carrying us forward until we raised our Series A. That loan and a small convertible note acted as our seed funding to allow us to get our first partners and start building the company.

Flash forward to the present: Lindy Biosciences recently raised more than $3.2 million. According to the filing, 29 investors contributed to the round. Can you tell us more?

Bitterfield: The Series B round was led by IAG Capital Partners. Good Growth Capital and Fulcrum Financial Partners also participated in the initial closing. The funds will be used to expand the team, move to a larger facility, and prepare for clinical trials with our partners. We plan to raise $5 million in this round and have raised around $3.7 million so far. (an SEC filing this week disclosed $3.25 million.)

Historically, women-led startups have a harder time raising funds. What’s your experience been?

Bitterfield: I was told it would take longer than I expected, and each round did take longer than I expected, so from that view I’d say it was typical. It’s certainly not easy to convince investors to take a chance on a first-time CEO. It requires communicating a clear vision and somehow convincing them you can execute it without much history. That was really challenging for early-stage funding, but we were able to get a great group of investors. Now I look forward to proving each year what my team and I can accomplish.

Where is Lindy headquartered? And how many employees do you have?

Bitterfield: We’re headquartered here in RTP at the Frontier campus with 13 employees. Stay tuned. We will be growing.

Talk us through the technology: What is microglassification dehydration technology? Where are you at in terms of development? How is it going to change people’s lives?

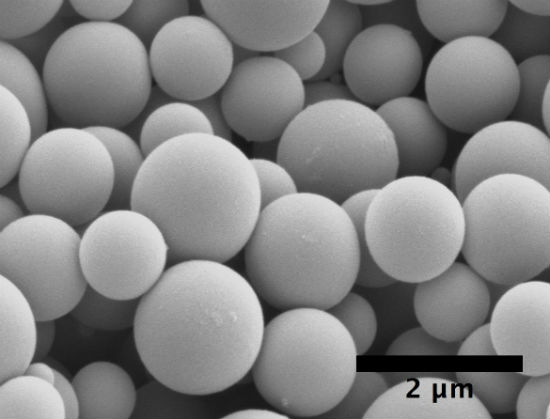

Bitterfield: Microglassification is part of a formulation platform for biologics that enables convenient, high-dose administration. Microglassification itself uses solvents to dehydrate small droplets of a biologic into a fine powder. We then suspend that powder in an oily vehicle suitable for subcutaneous injection. This allows us to combine the stability of a dry product with the convenience of a pre-filled syringe, and the ability to easily deliver high doses of a biologic.

High doses often have to be given through an IV infusion, so enabling subcutaneous administration is far more convenient for patients, giving them the option to self-administer at home. This also opens the door for more convenient dosing schedules and for new high-dose biologics.

We’ve been fortunate to have several great partnerships with pharma. We have very promising stability and preclinical data and look forward to moving into the clinic soon.

What do you wish you had known when you started Lindy Biosciences? And where would you like to see Lindy Biosciences in five years’ time?

Bitterfield: There’s no one thing I wish I had known. If I had known everything then that I’ve learned in the past few years, it would have been a quicker and easier road. But it’s also possibly not quite as fun.

I would like to see our suspension formulations advancing through the clinic and getting closer to helping patients. Beyond that I’d like to see Lindy develop into a broader drug delivery company. There are many applications for the technology that have only partly been explored.