Chapel Hill’s Jurata Thin Film Aims to Revolutionize Drug Delivery

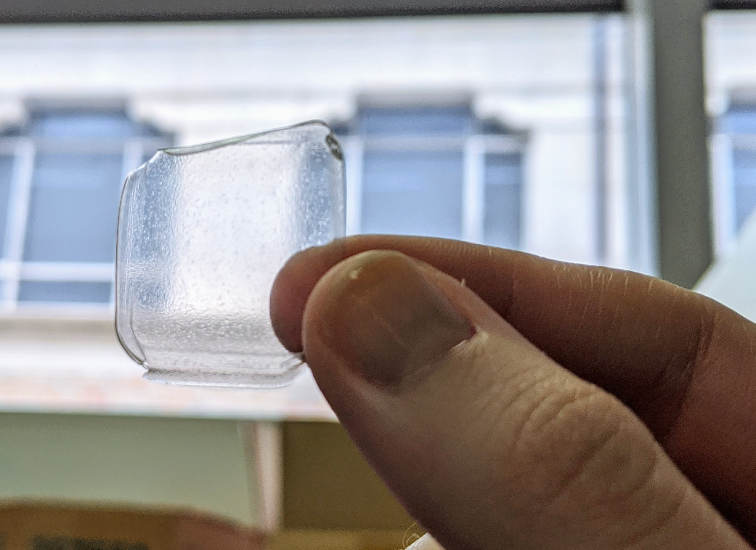

Imagine receiving a COVID-19 vaccine not from the jab of a needle and syringe but by slipping a thin, clear film smaller than a postage stamp inside your cheek or under your tongue and letting it dissolve.

That’s one of the potential benefits of a new drug-delivery technology being developed by Jurata Thin Film, a startup company in Chapel Hill that was co-founded by two of North Carolina’s most successful bioscience entrepreneurs.

Jurata’s thin-film technology preserves the therapeutic activity of biological pharmaceutics by immobilizing them into a solid film matrix, like the way amber can preserve ancient plant and insect specimens trapped within.

The technology allows vaccines and other lifesaving medications to be stored at room temperature for up to three years. This is in stark contrast to conventional vaccine production, which often requires freezing and storage at very cold temperatures to maintain potency.

“Our thin-film technology is able to stabilize many diverse payloads, which allows us to access myriad markets, including viral vector and mRNA vaccines, gene therapies, plasmids, therapeutic antibodies and many others,” said Megan Livingston, senior director of business development at Jurata.

“Our technology removes the need for cold chain logistics in pharmaceutical manufacturing, distribution and storage, significantly reducing costs for our clients and partners who develop the therapies,” Livingston added. “We have also shown that we can deliver vaccines, and potentially other biologics, without needles, so we are confident that many markets will buy into our technology.”

The technology also circumvents the need for lyophilization, or freeze-drying, an energy-intensive and costly bottleneck in conventional pharmaceutical manufacturing. Once thin films are produced, they can be shipped anywhere in the world and stored without temperature-control measures.

"Current pharmaceutical manufacturing technologies have significant shortcomings that limit the ability to mass-produce cost-effective therapies,” said Christopher M. Pavlos, Ph.D., Jurata's director of R&D. “Jurata's thin-film technology promises to eliminate these limitations."

Evidence supporting the thin film’s ability to store vaccines at ambient or elevated temperatures while maintaining therapeutic efficacy was published in Science Advances.

Texas roots, North Carolina base

Jurata’s thin-film technology was developed in the laboratory of Maria Croyle, RPh, Ph.D., a professor of pharmacy at the University of Texas at Austin, with the intention to deliver Ebola vaccines to people in low- and middle-income countries. Croyle is Jurata's chief scientific officer, overseeing research and development efforts to broaden the applicability of the company’s technology.

Research continues in her lab and at the Texas Medical Center in Houston, where Jurata has space at JLABS, an innovation incubator sponsored by Johnson and Johnson, the multinational health care conglomerate.

Jurata in 2021 was named a Blue Knight company, allowing it to receive access to JLABS resources along with mentorship from Johnson & Johnson and its partner, the Biomedical Advanced Research and Development Authority (BARDA), a federal agency responsible for the procurement and development of medical countermeasures against bioterrorism, pandemic influenza, and emerging diseases.

Croyle and her fellow co-founders and investors, North Carolinians Jude Samulski and Sheila Mikhail, established the company’s headquarters in Chapel Hill, because the town is part of the Research Triangle region, an area “ripe with biotech companies, both new and established, making it an optimal place to grow a new company in this industry,” Livingston said.

Samulski and Mikhail are also the co-founders of Asklepios Biopharmaceutical (AskBio), a gene therapy company in Research Triangle Park that was acquired by Bayer AG in 2020 for $2 billion up front and up to $2 billion in potential milestone payments.

The duo “immediately saw the potential in Jurata’s thin-film technology to stabilize adeno-associated virus (AAV) for gene therapies to treat ultra-rare and rare diseases, which would greatly ease our ability to treat patients around the world,” Livingston said. “Furthermore, we knew that extending the shelf life of gene therapies for ultra-rare and rare diseases, especially those supported by Columbus Children’s Foundation (with AskBio’s involvement), would drive down the costs of treating these patients by allowing us to manufacture more therapies at the same time and store them for longer.”

A recent publication with AskBio in Nature Medicine Communications indicates that Jurata’s thin-film technology is able to stabilize AAV therapeutics at room temperature for at least six months, “showing that the combination of these technologies has huge potential,” Livingston said.

“Jurata works with many different companies to thermostabilize their temperature-sensitive products and increase their accessibility to patients around the world,” she said. “AskBio is one of those companies, and we look forward to exploring opportunities with them.”

Compact vaccine shipping, storage

In the case of COVID-19 vaccines, Jurata’s thin-film technology could drastically reduce packaging and distribution challenges. About 8,000 uncut sheets of thin film “can hold more than 4 million vaccine doses, can be distributed in envelopes to anywhere in the world, and can be stored in a two-drawer file cabinet under a desk,” Croyle said.

According to estimates by the International Air Transport Association, the delivery of two doses of COVID-19 vaccines to the world’s 7.8 billion people would require 16,000 cargo planes.

“Jurata’s thin film could deliver the same volume in four cargo planes without any specialized shipping or storage needs,” Croyle said. “That is significant.”

That kind of potential made Jurata a finalist in Fast Company's 2021 World Changing Ideas Awards in the categories of Developing World Technology and Health. The awards program is focused on social good by “elevating finished products and brave concepts that make the world better.”

Jurata also recently participated in the WheelsUP Accelerator program, sponsored by BARDA and run by the First Flight Venture Center in Durham. The program, designed to help entrepreneurs scale disruptive biotechnology and health security solutions, finished with a pitch competition, which Jurata won, receiving $50,000 in research funding.

Seed funding in hand

In November 2022, Jurata raised $4.87 million in seed funding to develop its thin-film technology.

The funding was led by Golden Seeds, a network of angel investors committed to supporting women-led startup companies.

Other investors include Jurata's co-founders, Mikhail, Samulski and Croyle, and current employees. Additional contributions were made by institutional investors, including Columbus Ventures and Ferocity Capital, as well as UT Seed Investment Fund, a new fund intended to support startups based on technologies developed at the University of Texas at Austin.

The funding will help Jurata grow its three-person full-time staff to five early this year by adding two R&D positions.

It will also help the company establish a pilot manufacturing facility capable of fabricating over 1,000 doses of vaccine- or biologic-loaded thin films per hour.

The company is “evaluating multiple options” for the facility and can’t yet provide the location for it, Livingston said. “We hope to have it operational by late Q3.”

Funds will also be used to support the required toxicity studies demonstrating safety of Jurata's formulation for administration under the tongue, inside the cheek, or through intramuscular injection after rehydration.

"We are grateful for the support of our employees and investors, who champion our thin-film technology and are working tirelessly to hit critical milestones needed to get this in the clinic," Croyle said. "The ability to manufacture, distribute, store, and deliver lifesaving vaccines and biologicals, anywhere in the world, without any temperature-control measures will decrease costs and increase equitable access to these therapeutics."